Brake Systems

- Brake/Shift Levers

- Caliper Brakes (Road)

- Cantilever Brakes (MTB)

- Brake Levers

- Brake Shifter Combination Levers

- Brake Boosters

- Brake Cables

- Brake Carriers

- Brake Hangers

- Brake Pads

- Titanium Brake Hardware

Computers

Cranks and Chainrings

Forks

Frames & Framesets

Freewheels and Cassettes

Front Derailleurs

Grips

Handlebars

Handlebar Extensions

Headsets

Helmets

Hubs and Skewers

Lubricants

Metal Guide - Bicycle Metallurgy

Mirrors

Pedals and Toe Clips

Pumps and Inflation Systems

Racks

Rear Derailleurs

Rims & Rimstrips

Saddles

Seatposts and Binder Bolts

SRP Replacement Titanium &

Aluminum parts - Master Index

Stems

Tires

Tubes

Shoes

Spokes (Tables Only)

Tools - Bicycle Repair Tools

Yakima Fit List -to fit all cars

Notes

Links

Home

Mavic Road Rims

Mavic 700c diameter Road Racing clincher rims

MAVIC MA2

The Mavic MA2 is a double wall 700c road racing rim. As stated the series of alloy used for this rim kept secret. The MA2 is a Box shaped extrusion, with the three exterior surfaces, both side walls and the hub facing side of the spoke bed wall high polished to a bright Silver aluminum then Clear anodized to harden and preserve the finish. The extrusion is then drilled for the spoke and valve holes and rolled into its hoop shape. The ends are joined using an aluminum inset into the cavity between the cross-tie and spoke bed walls of the rim. The aluminum insert uses the rim ends as a "sleeve" to fasten and hold the ends tightly together. On our specimen for writing we noticed an un-common tiny hairline gap between the ends, but this un-common.

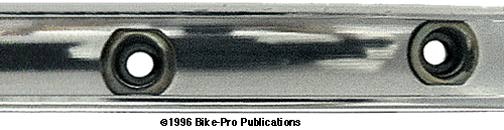

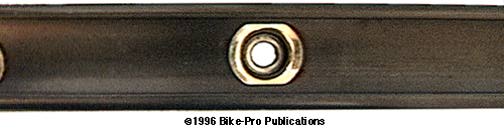

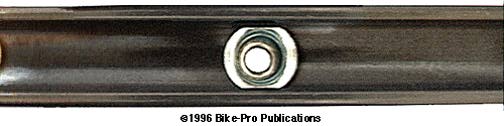

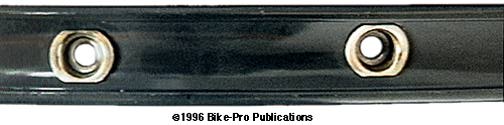

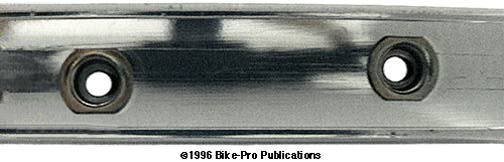

The MA2 uses two-piece, double wall stainless steel eyelets to prevent spoke nipple pull through rim failure. Both eyelet pieces are stamped from sheet stainless steel, the upper eyelet piece is cupped shaped, while the lower eyelet piece takes the form of a hollow rivet. The upper cupped shaped piece which has an oval seat, is inserted into the spoke hole from the interior or tire side. The lower piece is set into the upper cup piece, with the lower piece protruding though the spoke bed wall. Force is applied to the top of the lower piece so a can flare the lower piece into a smooth round blossom that holds both eyelet pieces firmly within the cross-tie and spoke bed walls. The spoke bed wall one of our production specimens of an MA2 showed a small amount of distortion from this peening process. The amount of force from the peening machine was set just a little high.

We sell the MA2 rim with 32, 36 or 40 spoke holes and a Presta valve drilling. More specifics about the rim are available in the Rim Table.

Mavic MA2 700c (Hole-2-6-0) $ Price in Catalog

MAVIC MA40

The MA40 rim is based on the same extrusion used in the MA2. The only obvious variation between the two rims is their surface treatment. They may each be made of a different series of aluminum alloy, but we'll never know because the alloy composition is kept secret.

The MA40 has their "CD" or "couche dure" treatment, what in the United States is called a hard anodized finish and is dark Grey in color. The anodizing on the MA40 is performed after it is hooped and drilled. All other aspects of the MA40 including the eyelets appear identical to the MA2 as explained above.

We sell the MA40 rim with 32, 36 or 40 spoke holes and a Presta valve drilling. More specifics about the MA40 rims are available in the Rim table.

Mavic MA40 700c (Hole-28-32-36-40) $ Price in Catalog

MAVIC OPEN 4 CD

The Mavic Open 4 CD is an extremely popular 700c clincher rim used by many, many road bike riders including a few that work here. The Open 4 is a "U" shape with sidewalls sloping out and upward from a narrower spoke bed wall achieving a flat sidewall for a braking surface for the upper third of the wall height. Each of the walls for this extrusion including the cross-tie wall exhibit a thin, delicate stability. Again, this rim's metallurgical composition remains a Mavic kept secret.

The Open 4 CD has Mavic's "couche dure", hard anodized Grey finish for a surface treatment. The hard anodizing is done after the rim has been rolled and joined into its hoop shape, and after it has been drilled for the spoke and valve holes. The ends of the rolled hoop are joined using an aluminum insert into the cavity between the cross-tie and spoke bed walls of the rim. It uses the rim ends as a "sleeve" to hold and retain the inner aluminum core. The joint holds the ends rigidly together, though we have noticed an occasional, small misalignment, raising one edge slightly, just a tiny bit, that the brake pad may grab.

The Open 4 CD uses two-piece, double wall stainless steel eyelets to prevent spoke nipple pull through rim failure. Both eyelet pieces are stamped from sheet stainless steel, the upper eyelet piece is cup shaped, while the lower eyelet piece takes the form of a hollow rivet.

The upper cupped shaped piece is taller in the Open 4 than other rims because of the section height of the rim and the distance between the cross-tie and spoke bed walls. The upper piece, having an oval flange, is inserted into the spoke hole from the interior, or tire side. The lower piece is set into the upper cup piece, with the lower piece protruding though the spoke bed wall. Force is applied to the top of the lower piece so a mandrel at the hub facing side of the spoke bed wall can flare the lower piece into a smooth round blossom that now holds both eyelet pieces firmly within the outer walls of the cross-tie and spoke bed walls. The spoke bed wall on the Open 4 CD showed no post machining distortion from this peening process.

We sell the Open 4 CD rim with 28, 32 or 36 spoke holes and a Presta valve drilling. More specifics about the rim are available in the Rim Table.

Open 4 CD 700c (Hole-28-32-36) $ Price in Catalog

MAVIC OPEN S.U.P. SBP and OPEN S.U.P. CD

The 700c diameter Open S.U.P. is the likely successor to the Open 4 CD. It has many of the features road cyclists will be looking for now that Mavic will be making welded rims. The welded style rims are referred to in the S.U.P. name which is explained in more detail in or description of the 117 S.U.P. rim listed further in this section. The Open SUP rim uses a "U" shaped, double wall extrusion. The extrusion is rolled into the rim's hoop shape, then the ends are inert gas welded together. After welding, the extra weld bead left in the interior of the rim where the tire seats is machined with a grinder to remove the "flash", and the exterior sidewalls are machined leaving fine circumferential ridges around the rim.

The machining on the sidewall at the joint, leaves the joint sidewall as smooth as the rest of the rim. After the surface machining, the rim is drilled for the spoke and valve holes, then hard anodized to a glossy dark Grey finish. At this point, the only physical evidence of the weld, on the sidewall, is a slight darkening where the weld occurred. This may be from the high temperature, or a slightly different aluminum alloy was used in the wire feed welder.

The Open S.U.P. uses a two-piece, double wall stainless steel eyelet to equalize spoke nipple stress and help prevent spoke nipple pull through failure. Both eyelet pieces are stamped from sheet stainless steel, the upper eyelet piece is cup shaped, while the lower eyelet piece takes the form of a hollow rivet. The upper piece, having an oval flange, is inserted into the spoke hole from the interior, or tire side. Because of the height between the cross-tie and spoke bed walls, the upper steel eyelet cup is taller than occurs on many other double wall eyelets. The lower piece is set into the upper cup piece, with the lower piece protruding though the spoke bed wall.

Force is applied to the top of the lower piece so a mandrel can flare the lower piece into a smooth round blossom that now holds both eyelet pieces firmly within the outer walls of the cross-tie and spoke bed walls. The spoke bed wall on the Open S.U.P. showed no post machining distortion from this peening process.

We sell the Open S.U.P. in a Silver anodized SBP (though it appears that Mavic is poised to discontinue this color) or the hard anodized CD finish in 28, 32 or 36 spoke holes with a Presta valve drilling. More specifics about the Open S.U.P. rim are available in the Rim Table.

CD 700c Grey (Hole-28-32-36) $ Price in Catalog

700c Silver (Hole-28-32-36 / S) $ Price in Catalog

MAVIC OPEN S.U.P. CD CERAMIC

Mavic also makes the Open S.U.P. CD with the ceramic coated sidewall. It is the same rim except it has ceramically treated sides. The process of ceramics, their use and how they are applied to the rim sidewall is discussed toward the end of the Mavic rims under the 117 SUP CD Ceramic.

We sell the Open S.U.P. CD Ceramic rim with 28, 32, or 36 spoke holes and a Presta valve drilling. More specifics about the Open S.U.P. CD Ceramic rim are available in the Rim Table.

Ceramic 700c (Hole-28-32-36) $ Price in Catalog

MAVIC MODULE 3 CD

The Module 3 is a 700c diameter that will accept tires wider than most racers will find comfortable. It's intended for Hybrid, Cross, tandem, or touring bikes which is why it's available in only 36 of 40 spoke hole drillings. It has many of the MA40's rim characteristics. The Mod 3 CD is a Box shaped rim with flat sidewalls. After the extrusion has been rolled into the hoop shape the ends are joined using and aluminum insert into the cavity between the cross-tie and spoke bed walls.

The aluminum insert uses the surrounding rim ends as a tight fitting "sleeve" to retain and hold both end together. After joining the end the rim is drilled for the spoke and valve holes, and it is then given the "CD" (couche dure), hard anodizing surface treatment that leaves the rim in a dark Grey yet smooth to the touch finish.

The Module 3 CD uses a two-piece, double wall eyelet to equalize the spoke nipple stress, and help prevent nipple pull through failure. Both eyelet pieces are stamped from sheet stainless steel, the upper eyelet piece is cup shaped, while the lower eyelet piece takes the form of a hollow rivet.

The upper piece, having an oval seat, is inserted into the spoke hole from the interior, or tire side. The lower piece is set into the upper cup piece, with the lower piece protruding though the spoke bed wall. Force is applied to the top of the lower piece so a mandrel can flare the lower piece into a smooth round blossom that now holds both eyelet pieces firmly to the cross-tie and spoke bed walls. The spoke bed wall on the Module 3 CD showed no post machining distortion from this peening process.

We sell the Module 3 CD rim with 36 or 40 spoke holes and a Presta valve drilling. More specifics about the Mod 3 CD rim are available in the Rim Table.

Mod 3 CD 700c (Hole-36-40) $ Price in Catalog

MAVIC MODULE 4

The Module 4 has been included in our work because there are a few riders in off road tandem, or touring conditions that need an extra wide 700c tire to go on a matching extra wide rim. The Module 4 is a double wall rim that has flat sidewalls and is made of a still held secret by Mavic series of aluminum alloy. After extruding the rim blank, the outer surfaces of the extrusion are high polished to a bright Silver aluminum finish then Clear anodized to preserve this bright finish.

The blank is then rolled into the rim's hoop shape and the ends are joined using an aluminum insert pressed into the cavity of both ends between the cross-tie and spoke bed walls. Each of the ends acts like a tight fitting sleeve, using the rim contour, to hold the ends tightly in place. One of the Mod 4 specimens we used for writing purposes showed a slight, tiny and un-characteristic gap between the joined ends. The Module 4 uses two-piece, double wall eyelets to equalize the spoke nipple stress and help prevent nipple pull through failure.

Both eyelet pieces are stamped from sheet stainless steel, the upper eyelet piece is cup shaped, while the lower eyelet piece takes the form of a hollow rivet. The upper piece, having an oval seat, is inserted into the spoke hole from the interior, or tire side. The lower piece is set into the upper cup piece, with the lower piece protruding though the spoke bed wall. Force is applied to the top of the lower piece so a mandrel can flare the lower piece into a smooth round blossom that now holds both eyelet pieces firmly to the cross-tie and spoke bed walls. The spoke bed wall on the Module 4 showed no post machining distortion from this peening process.

We sell the Module 4 rim with 36, 40 or 48 spoke holes and a Presta valve drilling. More specifics about the Mod 4 rim are available in the Rim Table.

Module 4 700c (Hole-36-40-48) $ Price in Catalog

MAVIC REFLEX ROAD RIM

Also at the conclusion of re-writing this section, Mavic made a new rim the Reflex SUP + UB. We haven't seen the rim yet but it is a 700 c road rim that has a welded seam and like the 217 has a machined side wall in the area of brake pad contact. The machining is performed after the rim is anodized so a very fine concentric line pattern is left on the side of the rim. The machined away, now un-anodized rim is said to have a better brake pad grip surface and its bare metal state is capable of greater heat disapation from braking.

The Reflex rim uses two piece stainless steel eyelet like those reviewed on the 281 rim. The Reflex rim comes in the TIB finish which a copper colored Brown/Gold finish. It is available in 28, 32, or 36 hole. These were just being shipped to us as this edition of the Buyer's Guide was being printed, so we didn't have any for measurments. Mavic believes the rim to weigh 430 grams.

Reflex SUP+UB TIB - 700c (Hole-28-32-36) $ Price in Catalog

Reflex SUP+UB SBP- 700c (Hole-28-32-36) $ Price in Catalog