Brake Systems

- Brake/Shift Levers

- Caliper Brakes (Road)

- Cantilever Brakes (MTB)

- Brake Levers

- Brake Shifter Combination Levers

- Brake Boosters

- Brake Cables

- Brake Carriers

- Brake Hangers

- Brake Pads

- Titanium Brake Hardware

Computers

Cranks and Chainrings

Forks

Frames & Framesets

Freewheels and Cassettes

Front Derailleurs

Grips

Handlebars

Handlebar Extensions

Headsets

Helmets

Hubs and Skewers

Lubricants

Metal Guide - Bicycle Metallurgy

Mirrors

Pedals and Toe Clips

Pumps and Inflation Systems

Racks

Rear Derailleurs

Rims & Rimstrips

Saddles

Seatposts and Binder Bolts

SRP Replacement Titanium &

Aluminum parts - Master Index

Stems

Tires

Tubes

Shoes

Spokes (Tables Only)

Tools - Bicycle Repair Tools

Yakima Fit List -to fit all cars

Notes

Links

Home

Araya Rims

JAPANESE RIM MAKERS

There are two note worthy rim makers in Japan, Araya and Ukai. They are note worthy because each of them has had their rims sold as original equipment on new bicycles and at one point both had their rims sold in the US as after market replacement parts. Both are well known for excellent quality and workmanship, however, at the moment, only Araya seems to have rims available in the US for after market replacements.

Ukai's participation in the United States parts distribution system dropped off beginning in the fall of 1987, after the G7 meeting drove the value of the dollar down and Japanese goods edged their way toward double the Yen price. Ukai is reported to have been the maker of the Specialized and also made the Ritchey rims that are sold on new bikes as original equipment. The Ukai manufactured Ritchey rims can be identified bt their welded rather than sleeved joint.

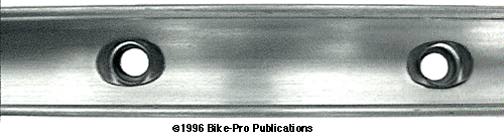

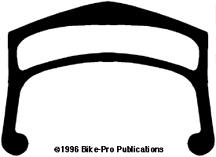

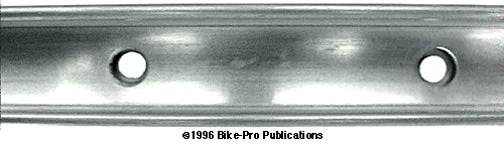

Sectional View of Araya joint.

Sectional View of Araya joint.

Both of these rim makers sell their goods through importer/distributors who have to make a value judgement in terms of what they think will sell to retailers in a reasonable period of time. The importer/distributor then places an order through a Japanese export trading company for delivery 90 to 120 days in the future. If they predict wrong they will have an overstock, tying up their capital. By nature, these organizations, when it comes to bulky items like rims, buy very conservatively which leads to occasional stateside shortages of either models, colors, or drillings.

ARAYA RM-17

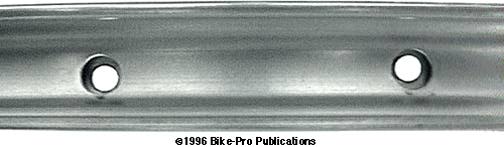

The RM-17 uses a Box shape extrusion of aluminum alloy as the basis for the rim. The series of aluminum alloy used isn't known. The double walled rim doesn't use steel eyelets to relieve spoke nipple stress and possible nipple pull through, but instead relies on added aluminum thickness in the spoke bed wall. The sidewalls of the RM-17 has a slight concave shape to it in the area of brake pad contact.

Once the extrusion has been rolled into the rim's hoop shape the ends are TIG welded together. The extra aluminum material, from the weld, inside the rim between the sidewalls is stripped away with a grinder. The exterior three sides, the outer sidewall and hub facing side are machined then polished removing all physical trace of the weld on the surface, leaving just smooth continuous rim sidewall for brake pad contact. Like the RM-20, the only evidence of the weld, is a slight, almost imperceptible, discoloration, within the smooth surface, at the joint from either the heat or the wire feed's alloy composition. After the hoop has been polished, it's drilled for the spoke nipple and valve holes, then anodized.

The rim is Clear anodized to leave it in a Silver color or hard anodized to the customary Grey color. We sell the 26" diameter RM-17 in either a 32 or 36 spoke hole drilling to accommodate a Schrader valve. For more specifics, please consult the Rim table.

26" x 32 hole (Color-GY-S) $ Price in Catalog

26" x 36 hole (Color-GY-S) $ Price in Catalog

ARAYA RM-20

The RM-20 has been in Araya's rim family for several years and has always been a worthy rim for mountain bike riders. The RM-20 is a double wall designed rim that places the cross-tie wall closer to the spoke seating wall than other rims of its kind and the inner bear width is wider than any of Araya's other rims. Its made of aluminum alloy, though its alloy composition isn't publicly known. The Box shaped rim doesn't use steel eyelets, but is extruded with a thickened spoke bed to help prevent spoke nipple pull through failure.

Unlike the other Araya rims we sell, the RM-20 has a flat sidewall, not concave. Once the rim is rolled into its hoop shape the ends are TIG welded together. The extra aluminum from the weld, the "flash" as it's known, is ground away from the interior, and the exterior three sides of the rim are machined and then polished leaving a smooth surface for the brake pad contact. The only evidence of the weld is a slight, very slight, discoloration of the joining aluminum wire used to fuse the two ends, but the smoothness of the rim makes it almost imperceptible.

Post polishing, it's drilled for the spoke and valve holes, then the rim is anodized in one of two colors, Clear leaving the rim Silver, or Hard Anodized to the customary Grey color. We sell the RM-20 in the 26" diameter both the Silver or the Grey finish with either 32 or 36 holes. We also sell the RM-20 in the 24" diameter, when available in the States, in Silver only with either 32 or 36 holes. The RM-20 comes typically drilled for a Schrader valve and more specifics are available in our Rim table.

26" x 32 hole (Color-GY-S) $ Price in Catalog

26" x 36 hole (Color-GY-S) $ Price in Catalog

RM-20 24" x 32 hole Silver $ Price in Catalog

RM-20 24" x 36 hole Silver $ Price in Catalog

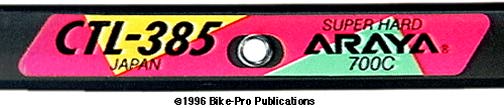

ARAYA CTL-385

The CTL-385 is was introduced in the 1992 model year. Araya makes it available to importer/distributors in both a 700c and 26" diameters, though we have seen it in the United States only in the 700c diameter. The CTL-385 has double wall construction, using a Box shape extrusion with slightly convex, (sloping outward) side wall. The lower wall of the extrusion, the spoke bed, is made slightly thicker than the side and the cross-tie walls, though the CTL-385 uses eyelets to equalize the spoke nipple stress.

Once the extrusion has been rolled into the hoop shape, the ends are joined using an aluminum insert into the cavity between the cross-tie and spoke bed walls of the rim. It uses the rim ends as a "sleeve" to hold and retain the inner aluminum core with a steel eyelet passing through the insert at both sides of the joint. We found the ends joined very smoothly on the specimen we wrote about. After joining the ends, the rim is anodized and the spoke and valve holes are drilled. The CTL-385 uses one-piece, double wall steel eyelets to prevent spoke nipple pull through rim failure.

The eyelet piece is stamped from sheet steel, forming the upper cup and flange shape, while the bottom eyelet piece takes the form of a hollow rivet. The eyelet is inserted into the rim from the interior or tire facing side of the cross-tie wall with the tubular rivet exposed through the spoke bed wall. Force is applied to the top of the rivet, so a mandrel at the hub facing side of the spoke bed wall can flare the lower rivet into a smooth round blossom that now holds the eyelet in place.

The spoke bed wall on the CTL-385 showed no post machining distortion from this peening process. We sell the CTL-385 rim in the 700c diameter with 32 or 36 spoke holes and a Presta valve drilling with a Silver or hard anodized Grey finish. More specifics about the rim are available in the Rim Table.

CTL-385 700C x 32 hole (Color-GY-S) $ Price in Catalog

CTL-385 700C x 36 hole (Color-GY-S) $ Price in Catalog

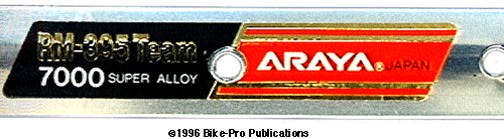

ARAYA 395 TEAM

The 395 Team is a 26" mountain rim, introduced in the 1993 model year. It has double wall construction and is made of 7000 series aluminum alloy. The Box shape extrusion has concave sides which slope and narrow from the spoke bed toward the top at the bead hook. The lower wall of the extrusion, the spoke bed, is made slightly thicker at the center where the spoke passes through and uses steel eyelet to even the spoke head stress and prevent a spoke nipple from pulling through the rim. Once the extrusion has been rolled into the hoop shape, its ends are TIG welded together. The excess weld material is machined away with a grinder on the interior of the rim, and the outer surfaces are carefully machined and polished leaving no visible evidence of the weld and an absolutely smooth brake pad contact surface.

The rim is Clear anodized leaving the aluminum in it's native Silver color, then drilled for the spokes and valve stem. Steel eyelet fastening is the last manufacturing step. The steel eyelet is the one-piece, double wall variety, meaning that one piece of steel plate is machine "cupped" to form the eyelet. The eyelet is pushed into the spoke hole from the rim interior. The eyelet flange is oval in shape with protruding ends facing in the direction of rim travel. To hold the eyelet, it is machine peened on the exterior, hub side of the rim.

Each of the eyelets on the 395 used for writing purposes showed some distortion of the aluminum around the eyelet peen, possibly the machine pressure was set a little too high on this batch of rims. We sell the 395 Team rim with 28, 32 or 36 spoke holes and a Presta valve drilling. Specifics about the rim are available in the Rim table. We noticed the irregularities in the weight to hole drilling relationship and double checked our weights, which were accurate. This relationship variation may be a product of extrusion wall thickness deviation.

RM-395 26" (Hole-28-32-36) $ Price in Catalog

ARAYA RM-400 PRO

The RM-400 was introduced in 1990. It uses double wall construction and is made of 7000 series aluminum alloy. The rim has a Box shape design with slightly concave sidewalls. The RM-400 Pro doesn't use eyelets to prevent spoke nipple pull through, but instead has a slightly thickened spoke bed. Once the extrusion has been rolled into its hoop shape the ends are joined by TIG welding them together. The welding "flash" left inside the rim is ground away. The three outer surfaces are smoothly machined and polished leaving no visible evidence of the seam or its weld for brake pads to hang up on. After joining the ends, and polishing, the rim is drilled for the spoke and valve holes then Clear anodized leaving it a Silver color. We sell the RM-400 Pro rim in either a 32 or 36 spoke hole with a Presta valve drilling. Specifics about the rim are available in the Rims table.

RM-400 26" (Hole-32-36) $ Price in Catalog